Technologies

NAPA’s key technology is Nano Imprint Lithography (NIL) invented in 1995 in the U.S, to reduce the size of microelectronic circuits. It is ranked among the revolutionary technologies by the MIT (« Ten Technologies That can change the world »), thanks to its generic scope and large variety of potential applications.

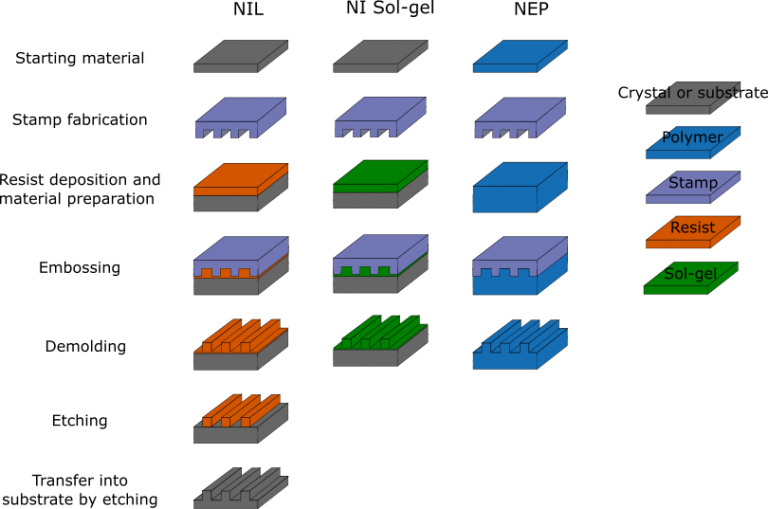

Schematically, a polymer deposited on the surface of the material, is embossed with a nano-structured stamp. Then the pattern is transferred into the material using the deformed polymer as a disposable etching mask.

In the traditionnal photo lithography process, the resist mask is processed by photo insulation through mask. There are limitations related to light interaction with the sides of the masks for nanoscale patterns. Using NIL the resist will be processed by plastic deformation using a hard or soft stamp.

NAPA develops processes, materials and micro nano patterns to meet its client’s requirements. Along the years, NAPA tuned various solutions to be able to pattern any material. We are able to pattern large surfaces (10sx10s of cm) on flat but also on 2.5D (lens shape substrates).

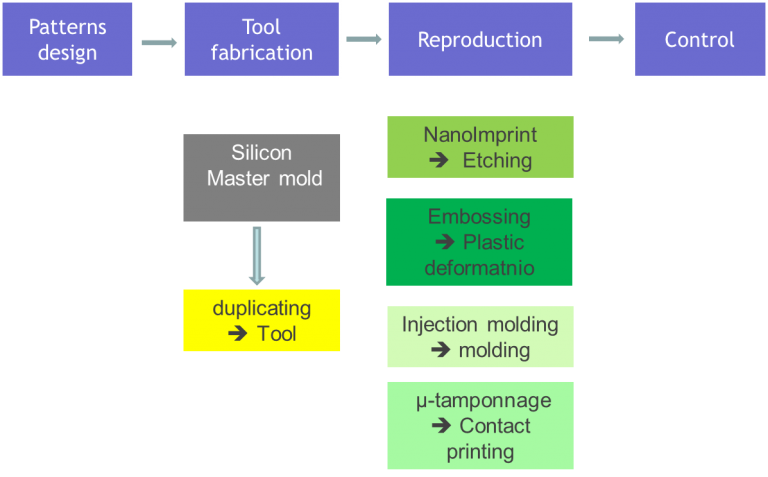

NAPA is active on the whole process flow, from the design of functional patterns (for optics or wettability) down to process control :

- Design of patterns including simulation and modelling

- Manufacture of tools at micro and nanoscale

- Transfer patterns on a range of materials by etching plastic deformation molding or contact printing

- Geometric and functional characterizations such as wetting proporties or diffraction effects